Items during on-site inspection of photovoltaic power station operation and maintenance and technicians include: infrared camera (hot spot inspection), stain occlusion loss, photovoltaic module performance degradation, photovoltaic cluster string temperature rise loss, photovoltaic module/string series and parallel mismatch loss, EL test, photovoltaic array mutual occlusion loss, DC line loss, inverter efficiency, inverter MPPT efficiency, transformer efficiency, AC line loss, photovoltaic array insulation test, grounding continuity test, grid connection performance test (grid connection point power quality, island protection, active/ reactive power control ability, low voltage ride-through and voltage/frequency adaptability verification) and other test contents.

In the test project of the photovoltaic power station using string inverters, it should be determined according to the actual situation.

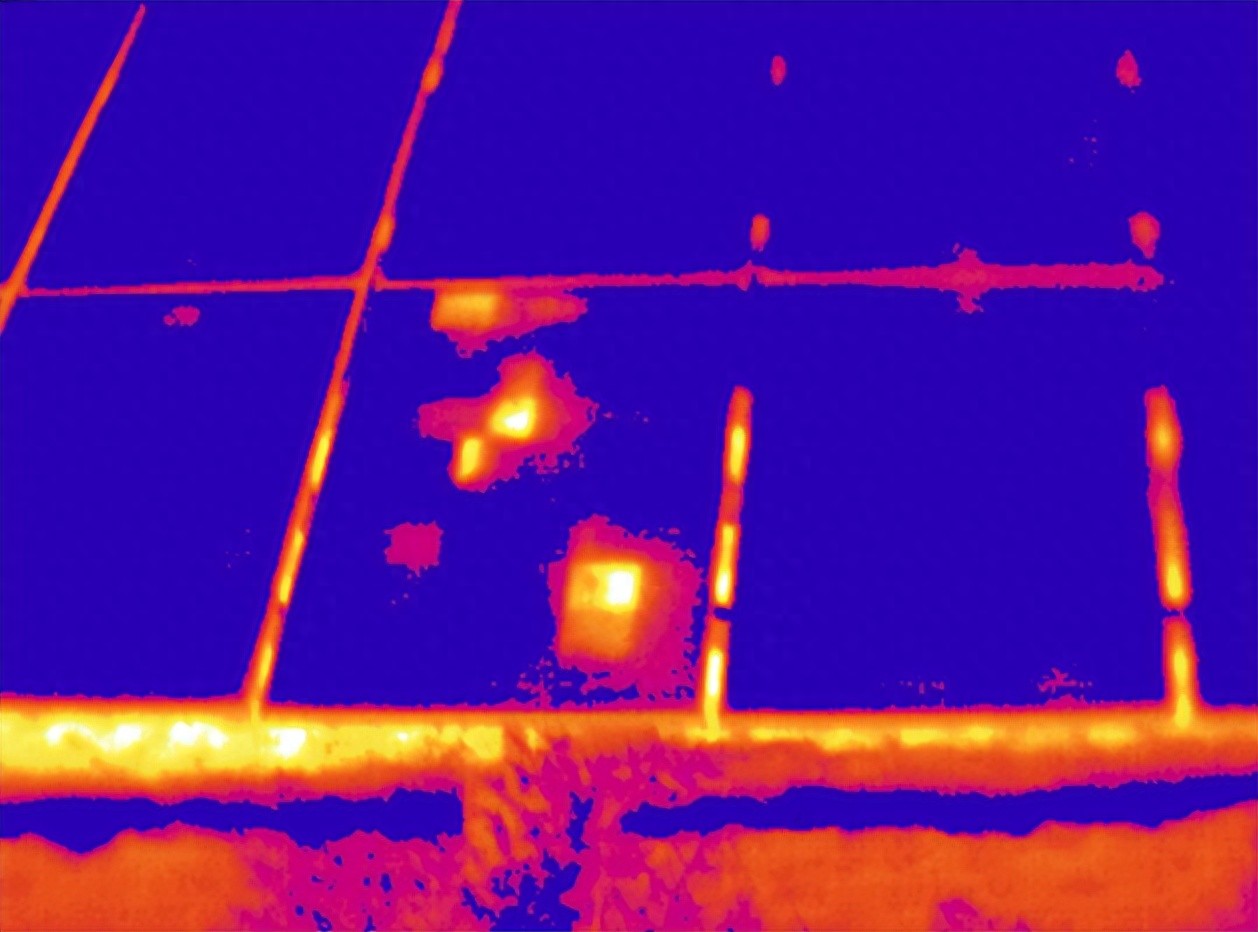

1. Infrared (IR) scanning inspection of photovoltaic modules (full inspection using drones)

(1) When the photovoltaic operation and maintenance personnel scan the photovoltaic modules by infrared scanning, the photovoltaic array should be in normal working condition during detection, and the irradiance of the array should be higher than 600W/㎡ to ensure that there is enough current to generate high temperature in the problematic part.

When the temperature difference directly above the cell on the outer surface of the same module exceeds 20°C, it should be regarded as a hot spot.

Infrared scanning should focus on battery hot spots, problematic bypass diodes, junction boxes, solder tapes, connectors, etc.

If there are hot spots, obvious yellowing and discoloration should generally be seen in the hot spots.

2. Photovoltaic system stains and dust shielding losses

If there is a dust accumulation monitoring reference sheet (the short-circuit current of the photovoltaic cell has a linear relationship with the dust occlusion degree or irradiance), the dust accumulation occlusion loss value of the reference sheet at that time will be retrieved. For photovoltaic modules or photovoltaic arrays, the decrease of short-circuit current is consistent with the decrease of power under uniform dust accumulation conditions, and the decrease of short-circuit current is different from the decrease of power under non-uniform dust accumulation conditions. In order to compare the relationship between irradiance loss and power loss, in addition to obtaining the data of the reference sheet, the dust accumulation loss should be actually tested according to the following method and compared with the monitoring results of the reference sheet.